Not known Factual Statements About gearbox cvt

Not known Factual Statements About gearbox cvt

Blog Article

En raison des poulies et de la courroie, il est difficile de canaliser une importante puissance sans avoir de glissement. Il y a également une légère perte de frein moteur par rapport à une transmission automatique conventionnelle.

Simplified Management. Procedure in the complete choice of ahead and reverse speeds may be controlled making use of an individual lever or maybe a foot pedal to actuate a diversion valve or variable-displacement pump.

Some drill presses and milling equipment comprise a simple belt-travel CVT system to manage the velocity of the chuck, such as the Jet versions J-A5816 and J-A5818.[50] In This technique, the productive diameter of just the output shaft pulleys is constantly variable. The enter pulley connected to the motor is usually mounted in diameter (or often with discrete methods to allow a selection of pace ranges).

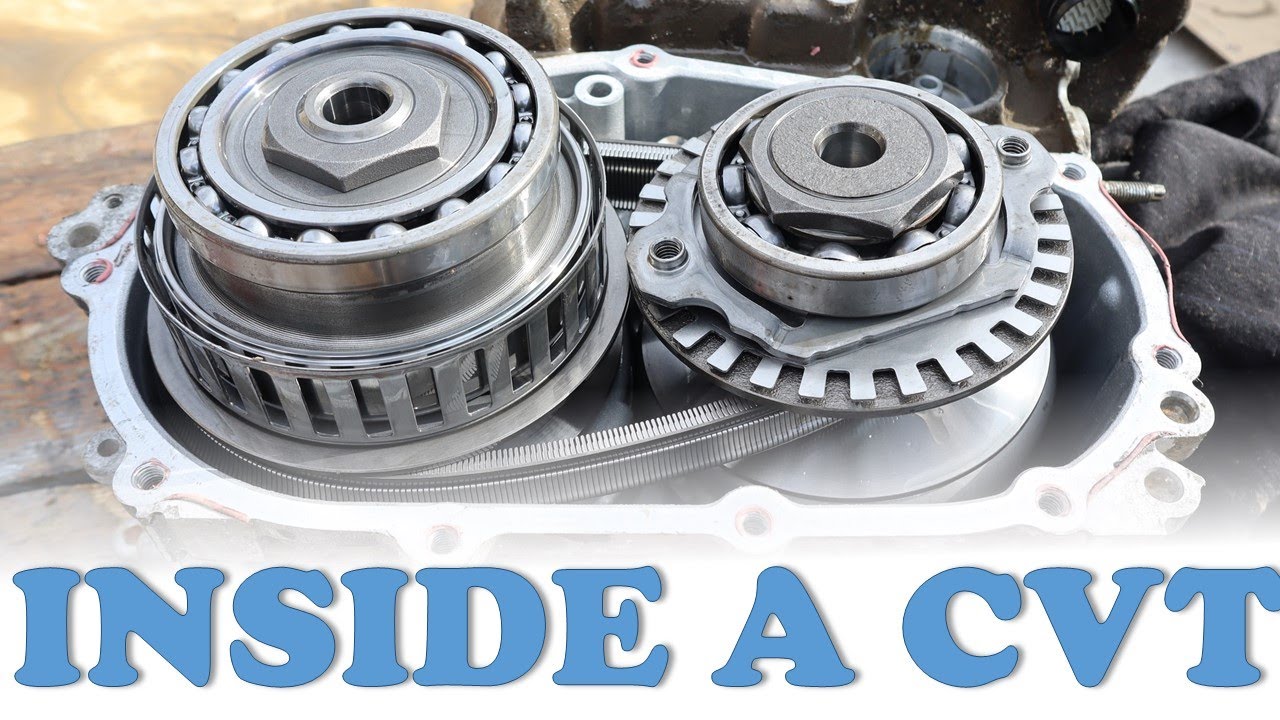

Whilst this type of procedure looks substantially different, most of the factors are analogous to your belt-and-pulley system and lead to precisely the same effects -- a repeatedly variable transmission. Here is how it works:

The most typical variety of CVT uses a V-belt which runs concerning two variable-diameter pulleys.[2] The pulleys encompass two cone-formed halves that shift jointly and apart. The V-belt runs between both of these halves, so the successful diameter with the pulley is dependent on the distance amongst the two halves of the pulley.

In a very hydrostatic CVT, the successful "equipment ratio" in between the motor and also the driving wheel(s) is the result of a distinction between the pump's displacement—expressed as cubic inches or cubic centimeters for every revolution—and also the motor's displacement.

Lightweight and Compact: A CVT is usually lighter plus much more compact than a standard automatic transmission. This may result in a lighter All round car fat, which often can make improvements to handling and performance.

John Goreham is often a lifetime-extended vehicle nut and recovering engineer. John’s concentration places are technologies, safety, and inexperienced automobiles. During the nineties, he was part of an educational group that crafted a solar-electric powered motor vehicle from scratch. His was the role with the battery thermal Manage designer. After earning his engineering diploma, John also finished a advertising and marketing plan at Northeastern College. For 20 years, he applied his engineering and gross sales skills inside the worlds of semiconductor manufacturing, biopharmaceutical output, and automotive electronics offer chain.

Hello Barb, I’ve examined the Impreza and haven’t seasoned that situation. All I'm able to Imagine is its down to how you’re using the accelerator? CVTs don’t are inclined to love on, off driving that may see them jerk a little, but then the same can be stated of DSGs at reduced speeds. I’d will need more info.

Your transmission difficulties are significantly reduced because of using hydraulics and elimination of friction-inclined points of Call.

Simple English clarification!! Everybody should read through this and check out a minimum of some distinctive CVT’s before saying all are rubbish.

A further approach would be to utilize a variable displacement pump. When the pump is configured for very low displacement, it creates a small volume of terus ke sana oil move, triggering the hydraulic motor(s) to turn additional slowly and gradually.

The CVT consists of various elements that work jointly to provide the continual array of gear ratios. These components include things like:

The design basic principle dates back to prior to the 1930s, with the first design and style meant to convert rotary movement to oscillating motion and back again to rotary movement utilizing roller clutches.[eighteen] This design stays in output as of 2017, to be used with reduced-pace electric powered motors.